| Research Facilities |

|

Equipment Name: 3D Surface Roughness Measuring-cum-Contour Tracing Equipment

Model: MarSurf LD 130 with measuring stand ST 500 CNC

Manufacturer: Mahr Gmbh Germany

Uses: For contact three-dimensional measurement different parameters of surface roughness and for tracing the contours of any surface using different types of probes.

|

|

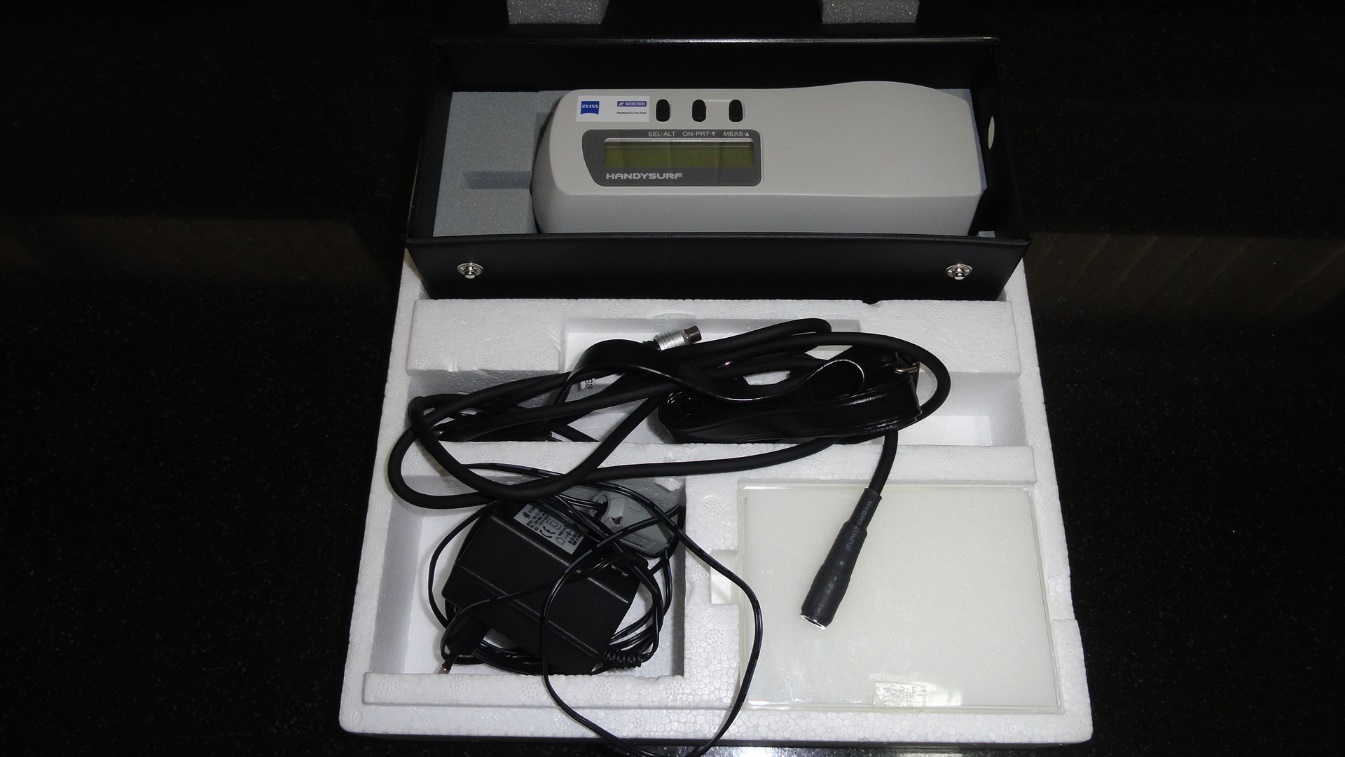

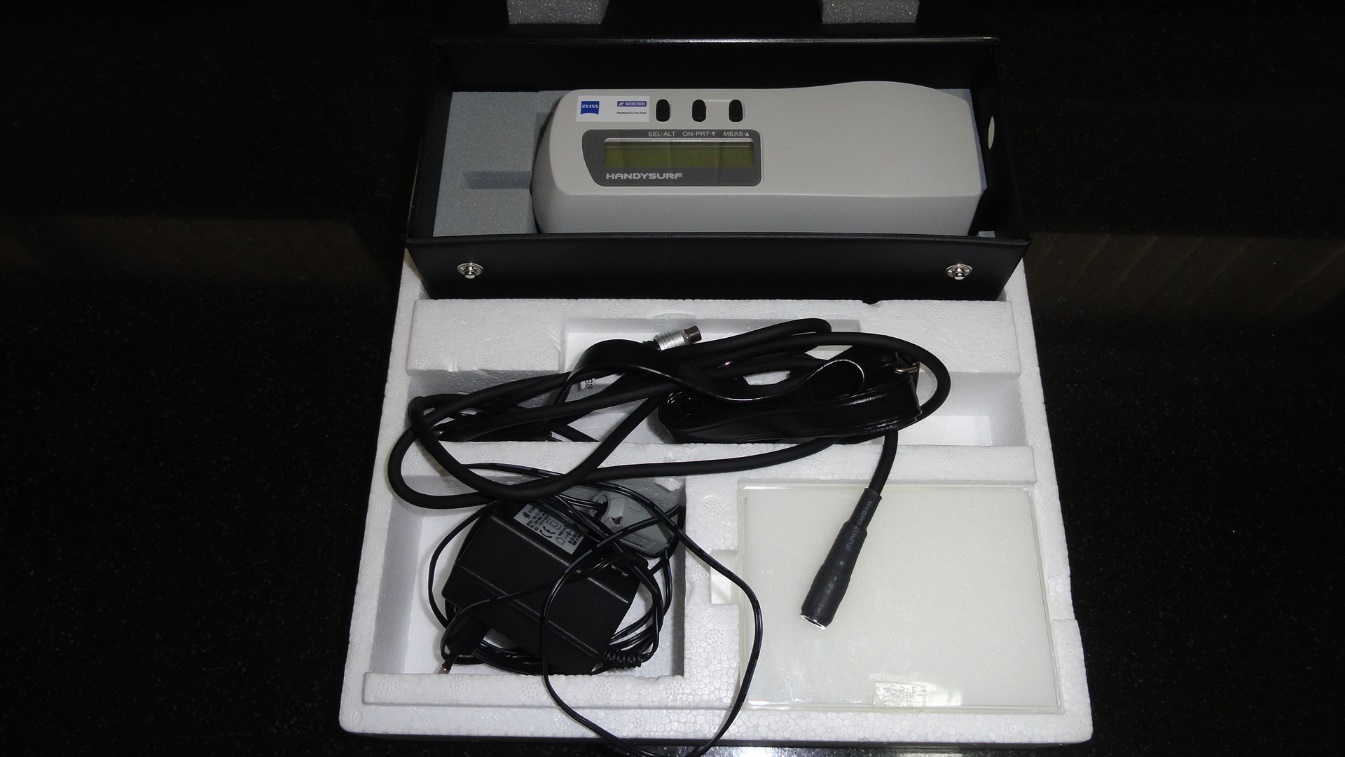

Equipment Name: Stylus type surface roughness measuring device

Model: Handysurf E-35B

Manufacturer: Handysurf E-35B: Hand-held perthometer for the measurement of various parameters of surface roughness parameters as per DIN, ISO standards. Resolution 10 nm; Range: 12.5 mm

Uses: For quick contact-type measurement of surface roughness parameters such as Ra, Rmax, Rz etc. as per DIN, ISO standards.

|

|

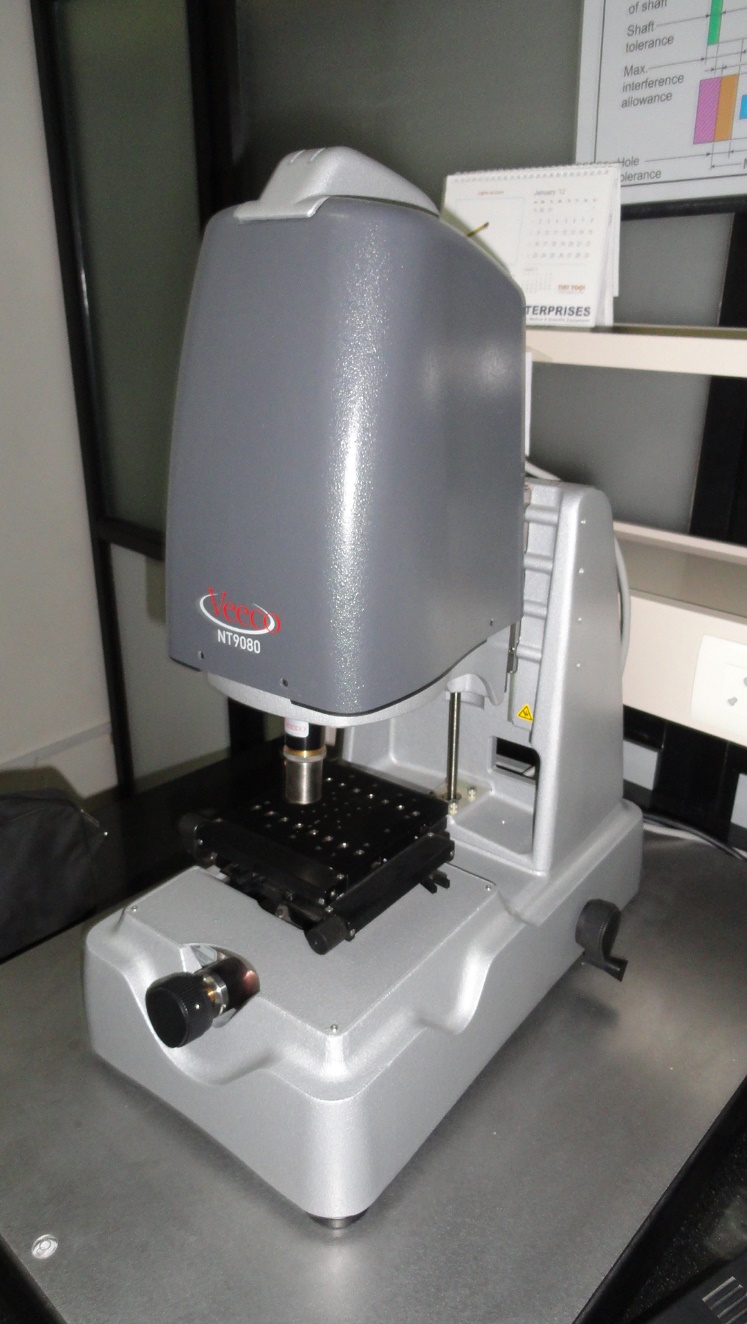

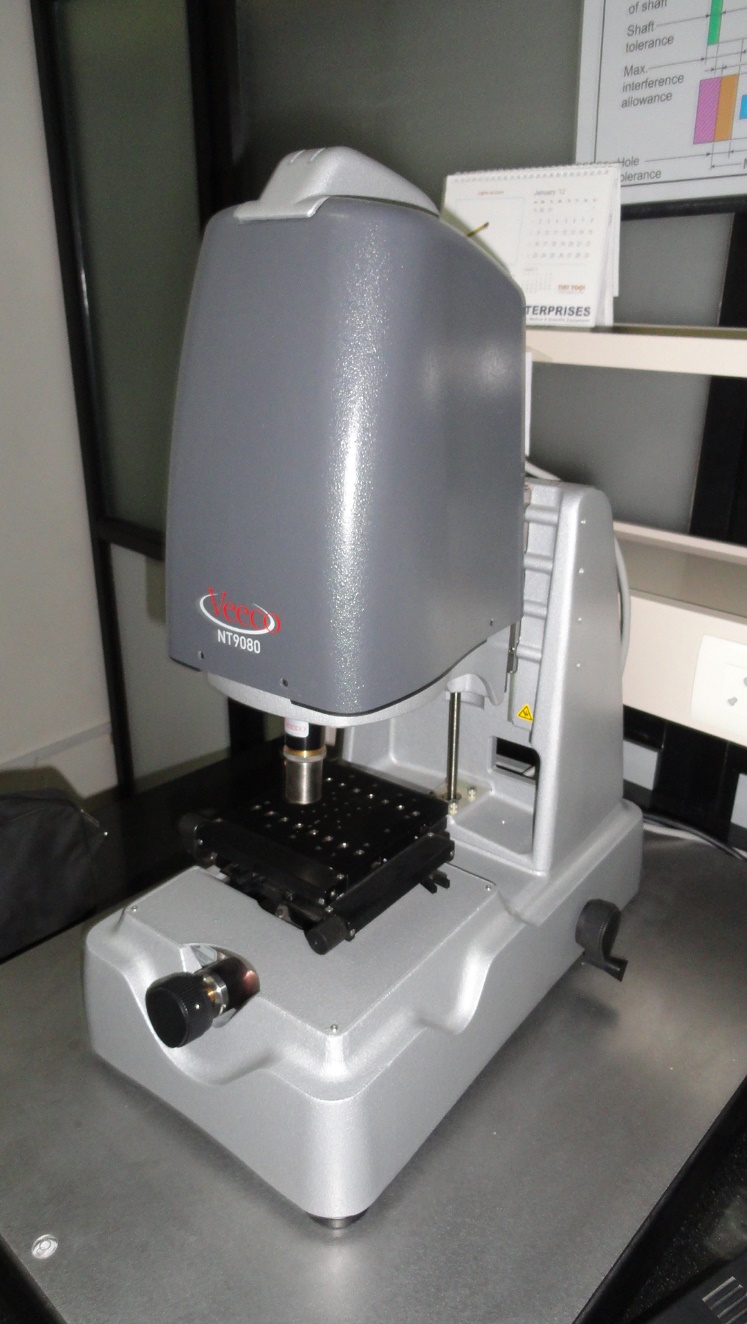

Equipment Name: Optical Surface Profiler

Model: NT9080 along with Vision 32 software

Manufacturer: Bruker Instruments, USA

Uses: For non-contact measurement of different parameters of surface roughness.

|

|

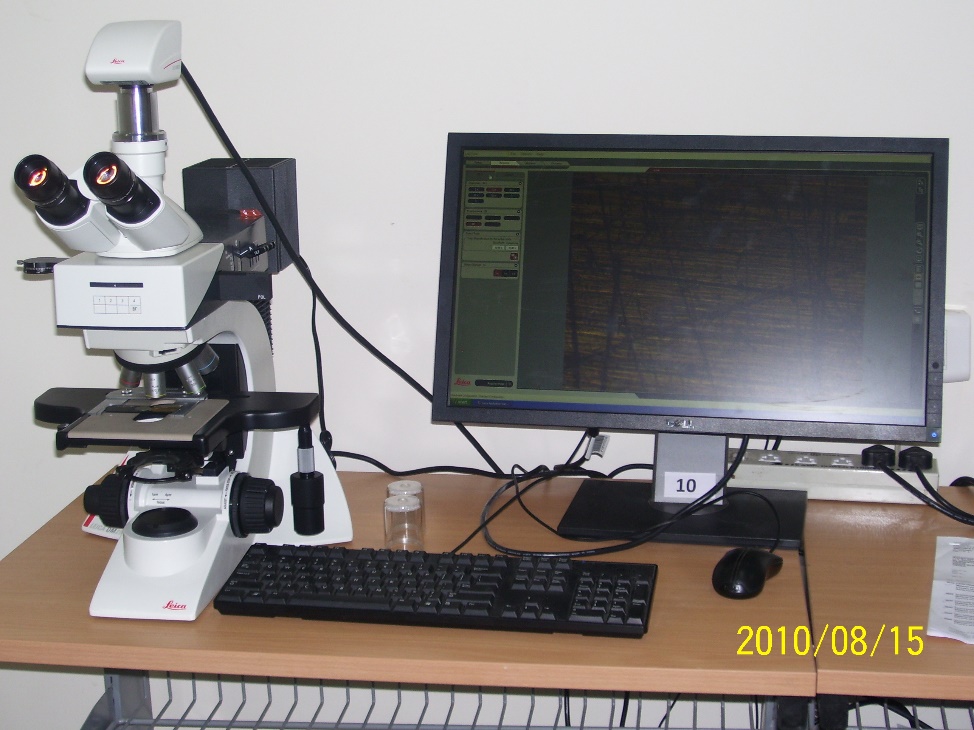

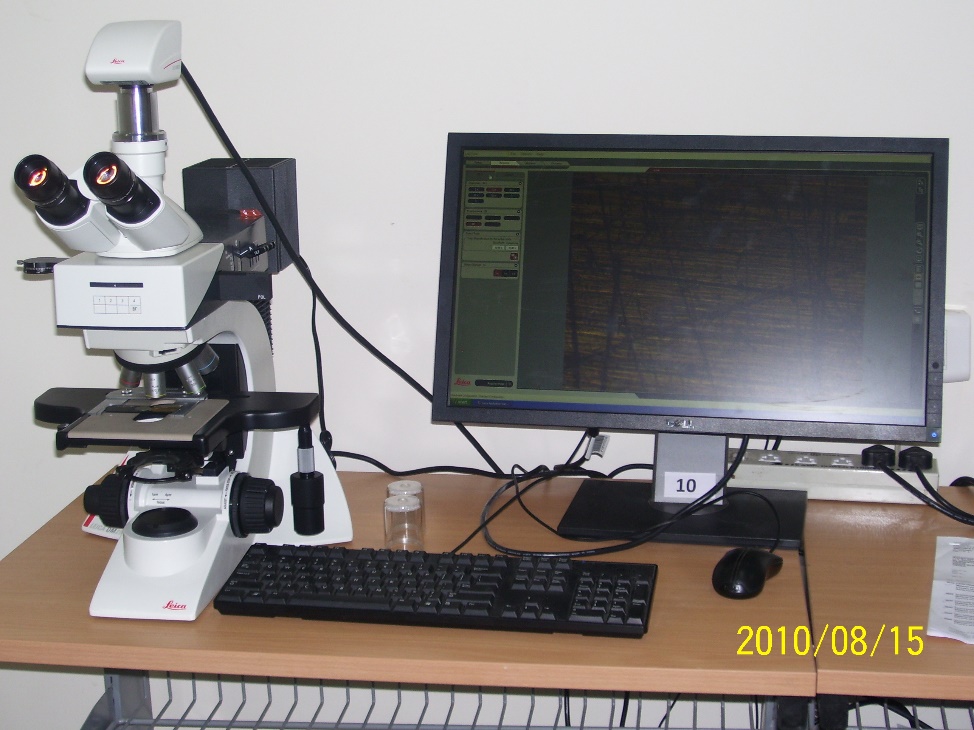

Equipment Name: Optical Microscope

Model: DM 2500M along with Polarizer attachment, 100x objective EPI, Digital imaging system, Image analysis software (Leica QMW), Software for advanced metallurgical analysis (Leica QMetals)

Manufacturer: Leica Microsystems, Germany

Uses: For optical micrography with 1000x magnification of different samples manufactured/fabricated by different processes.

|

|

Equipment Name: Form tolerances measuring system

Model: MarForm MMQ 200 T7W: High precision measuring axis polar; Motorized horizontal and vertical axes; motorized probe; Ergonomical operator panel.

Manufacturer: Mahr Metrology, Germany

Uses: To assess the deviations of form and location tolerances such as Straightness, Flatness, Roundness or circularity, Cylindricity. Conicity, Taper, Angularity, Parallelism, Perpendicularity, Concentricity or Coaxiality, Angular sector, Run-out, Total run-out etc. as per DIN/ISO standards and document them.

|

|

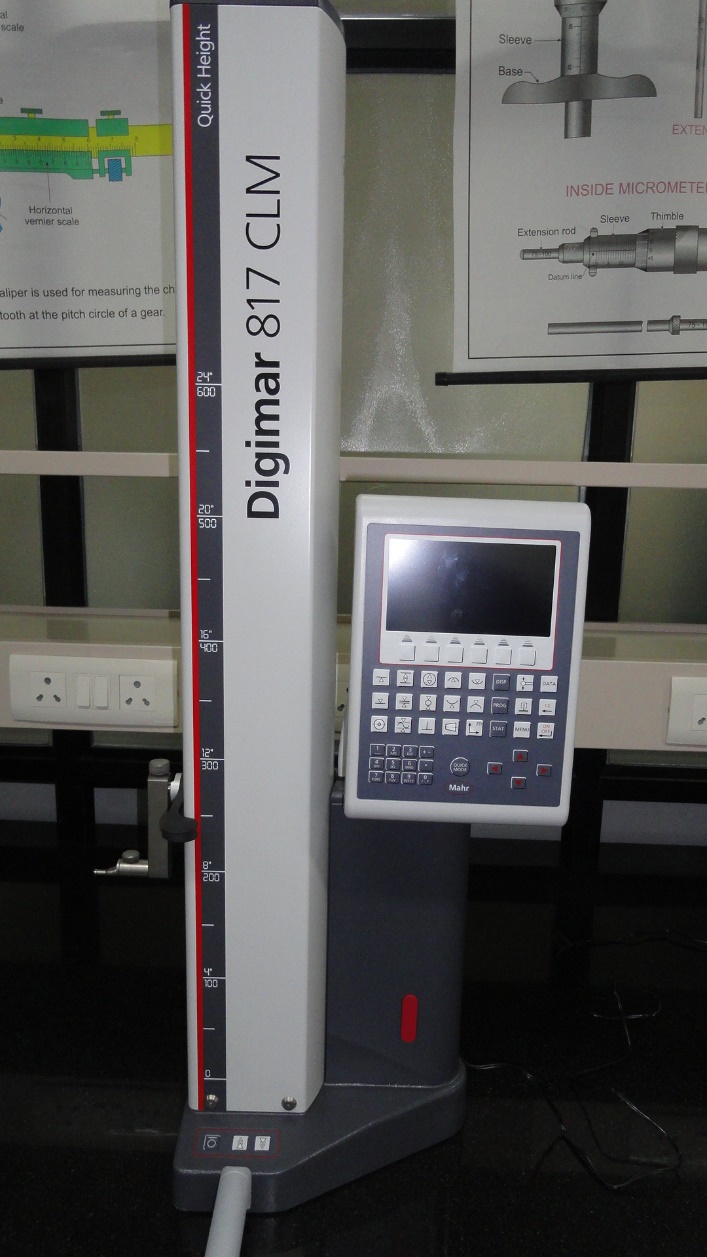

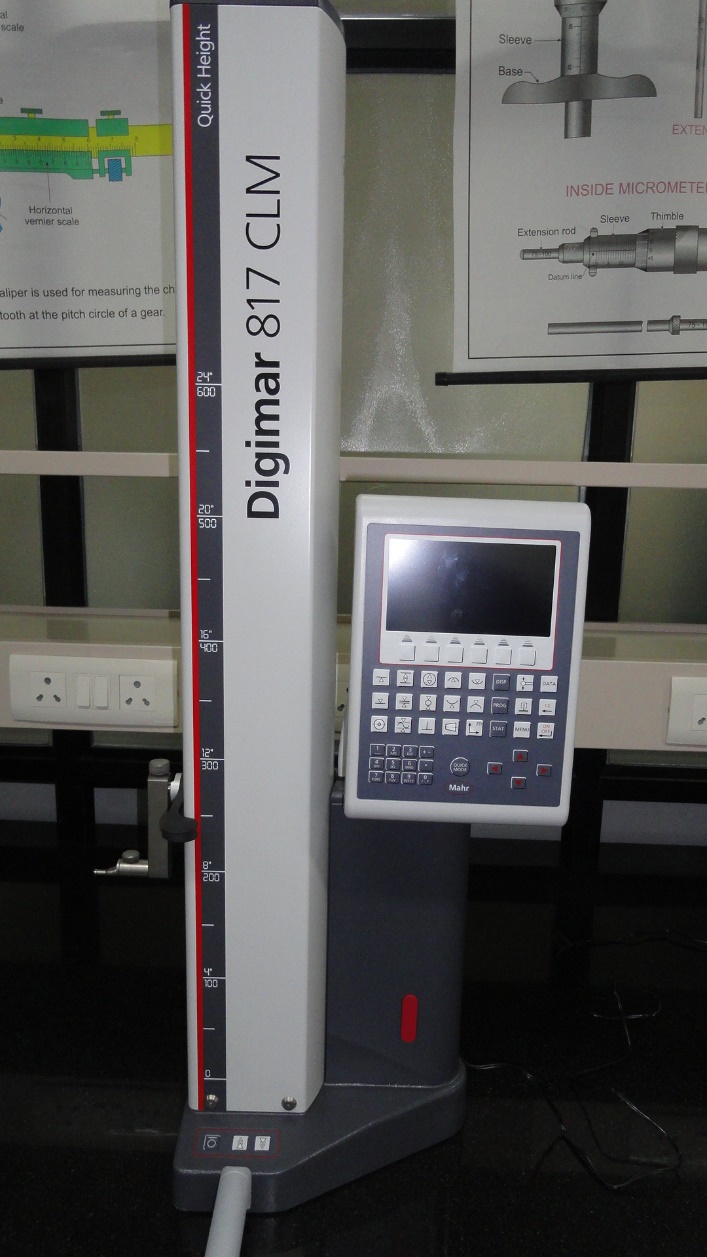

Equipment Name: Height Measuring Instrument

Model: 814 S: Height Measuring and Scribing Instrument: Range: 350 mm, Resolution: 0.01 mm, Stainless Steel, RS 232 data output

817 CLM: 2-Dimensional Digital Height Measuring Instrument with accessories set 817 ts 1 and 817 h3 Carrier (Range: 600 mm; resolution 0.001 mm) and with Marcom software and USB and RS 232 connectors

Manufacturer: Mahr Metrology, Germany

Uses: Measurement of center-to-center distances of holes, Shape tolerances of prismatic parts.

|

|

Equipment Name: Contour measuring system

Model: CONTRACER CV-3100 S8: Measuring Range (X-axis): 200 mm; Resolution 0.05 µm

Manufacturer: Mitutoyo Japan

Uses: High precision contour measurement device with capability to (i) Determining radii, distances, angles, coordinates, line and form deviations, (ii) Tolerance monitoring, (iii) Performing nominal/actual comparisons, (iv ) Creating points, intersection points, free points, center points, maximum and minimum points, (v) Creating regression straight lines and circles.

|

|

Equipment Name: Slip gage or Johnsons gage block

Model: MarGage 406/0-87: M81 Grade 0 standard Slip gage or Johnsons gage block made of steel with calibration Certificate

Manufacturer: Mahr Metrology, Germany

Uses: End standard for calibration of all linear measurement equipment.

|

|

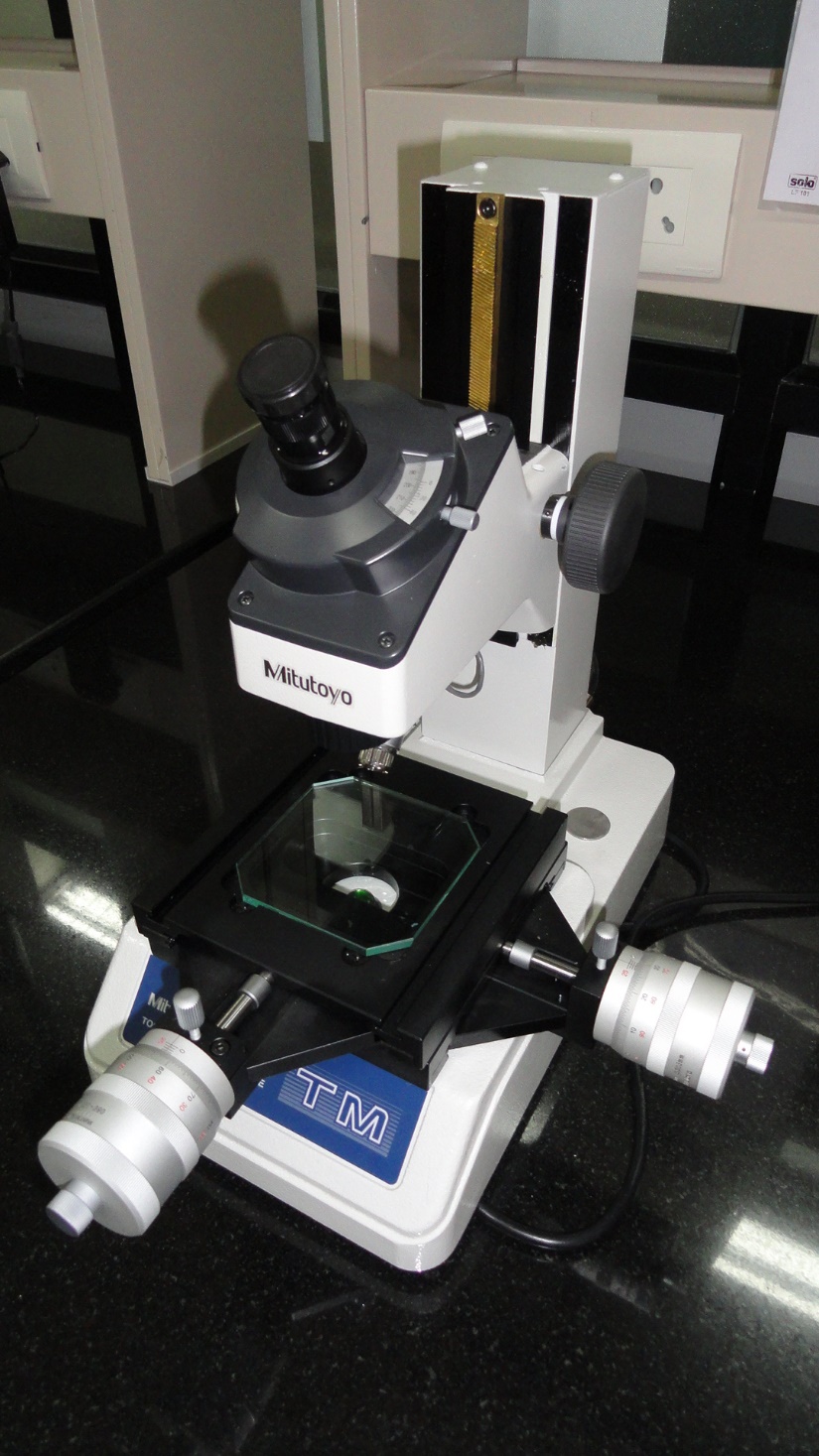

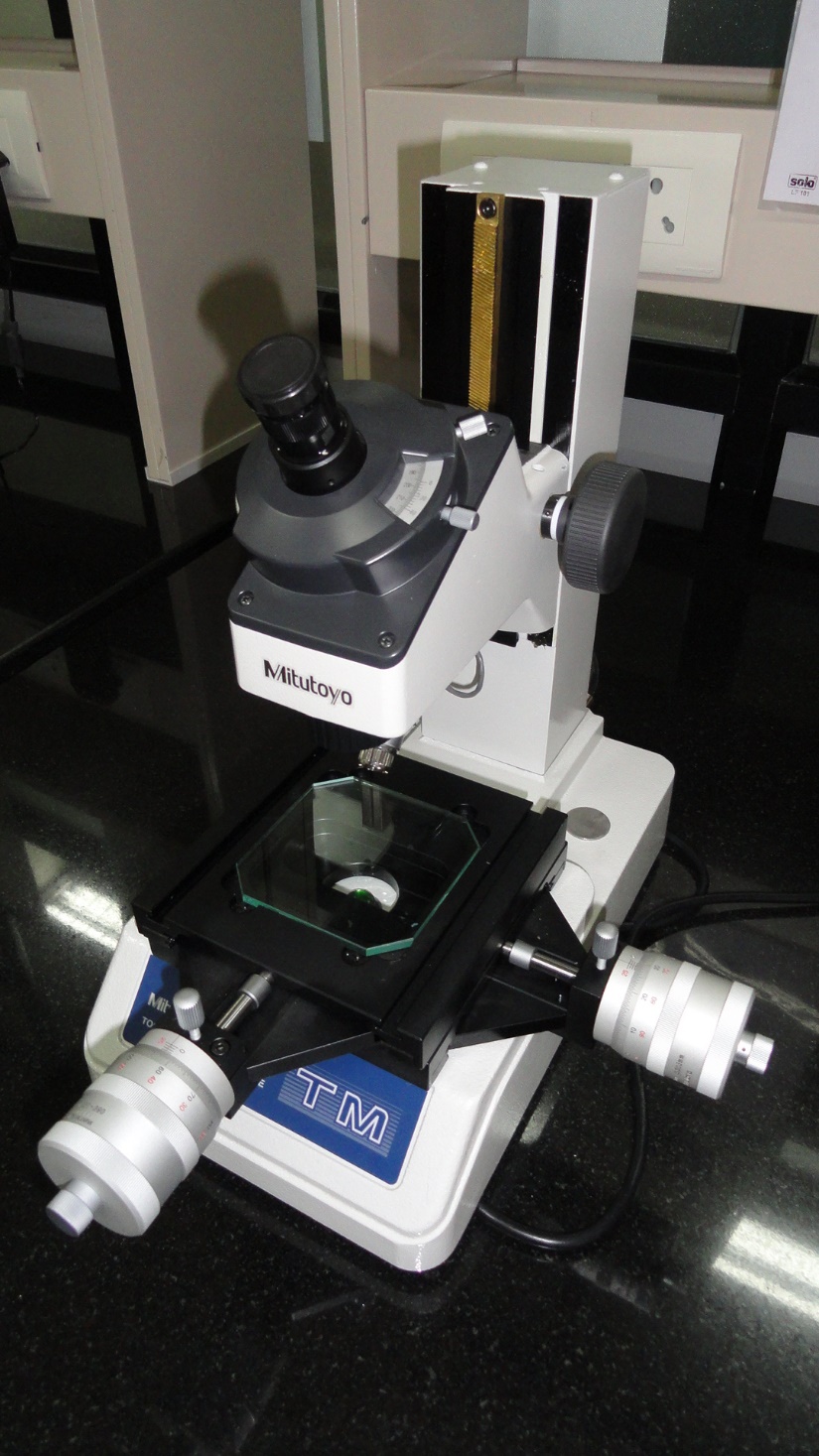

Equipment Name: Toolmaker's Microscope

Model:T M 505: Eyepiece magnification 15x and objective magnification 2x, monocular with 30 degrees depression angle, Max. Specimen height 115 mm, maximum workpiece load 5 kg.

Manufacturer: Mitutoyo Japan

Uses: For measurement of cutting tool angles, parameters of threads

|

|

Equipment Name: Computer numerical controlled (CNC) coordinate measuring machine (CMM)

Model: Spectra 567

Manufacturer: Accurate Gaging & Instruments, Pune

Specifications: Measurement range X axis: 500 mm; Y axis: 600 mm; Z axis:400 mm; Resolution 0.5 µm; Repeatability 0.002 mm; Reninshaw probing system (MH20i), Granite table

Uses: For automatic measurement of different types of geometrical tolerances

|

Different other measuring equipment available

- Bench micrometer with 3-wire thread measuring system: Model 313-101: ranging pitch from 0.25-4 mm meets all ANSI and ISO spec.

- Gages for Internal Measurement: Marameter 838 T1: Three units to cover measuring range 5-15 mm with resolution 0.005 mm; and measuring range 10-30 mm; and 30-50 mm with resolution 0.01 mm) with Calibration Certificate

- Digital and analog Vernier and micrometers

- Sine bar

- Thread micrometer

|

|

Equipment Name: CNC Wire-EDM Machine

Model: Ecocut

Manufacturer: ELECTRONICA MACHINE TOOLS, PUNE

Specifications:

Main Table Traverse (X, Y): 250, 350 mm;

Max. work piece weight: 300 Kg;

Max. Taper cutting angle: ± 5°/100 mm;

Max. wire spool capacity: 6-7 kg;

Memory: 1000 blocks with battery backup;

Power Rating

Motor Power: 3KVA; 3 Phase; 415 Voltages.

|

|

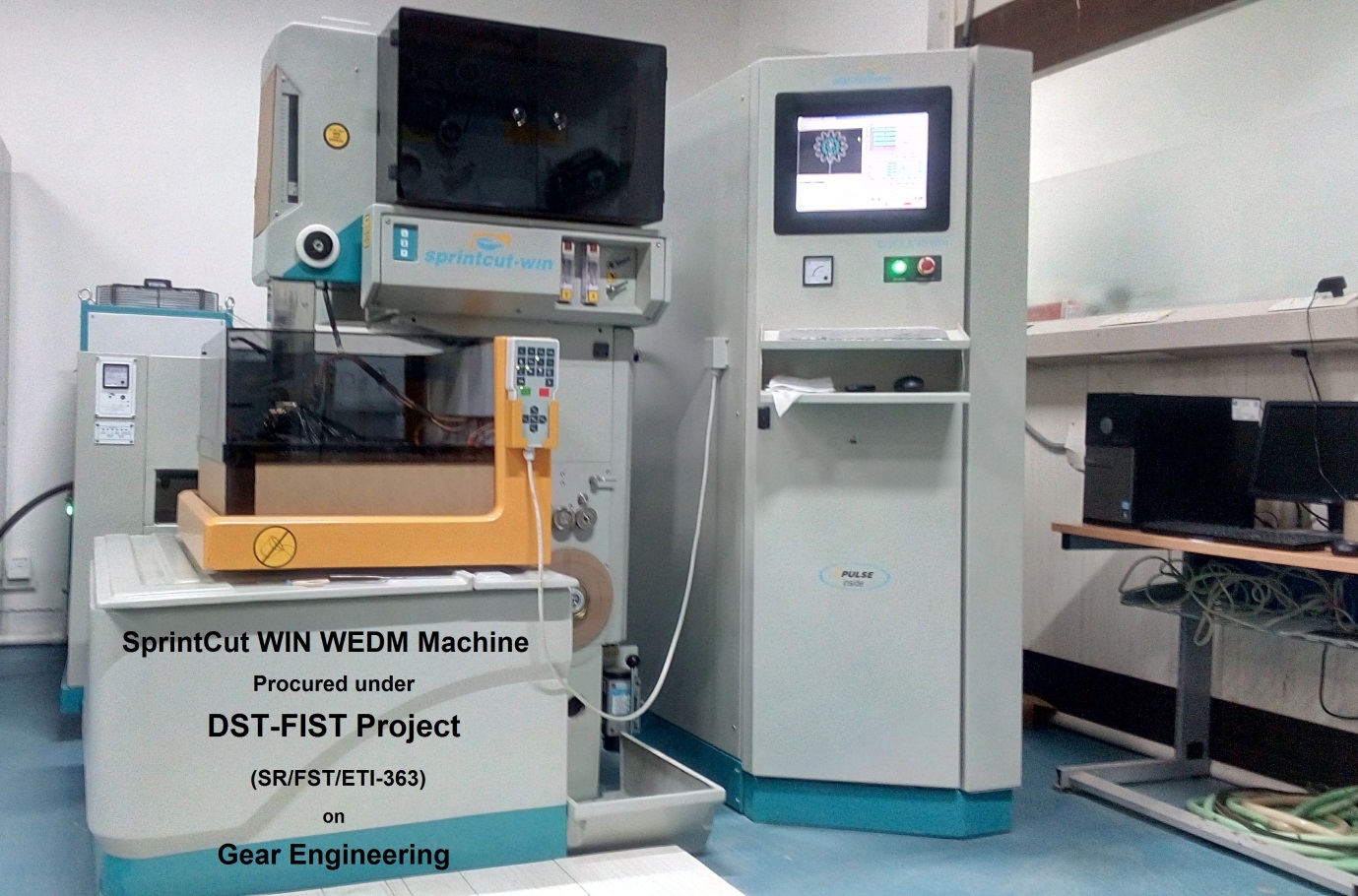

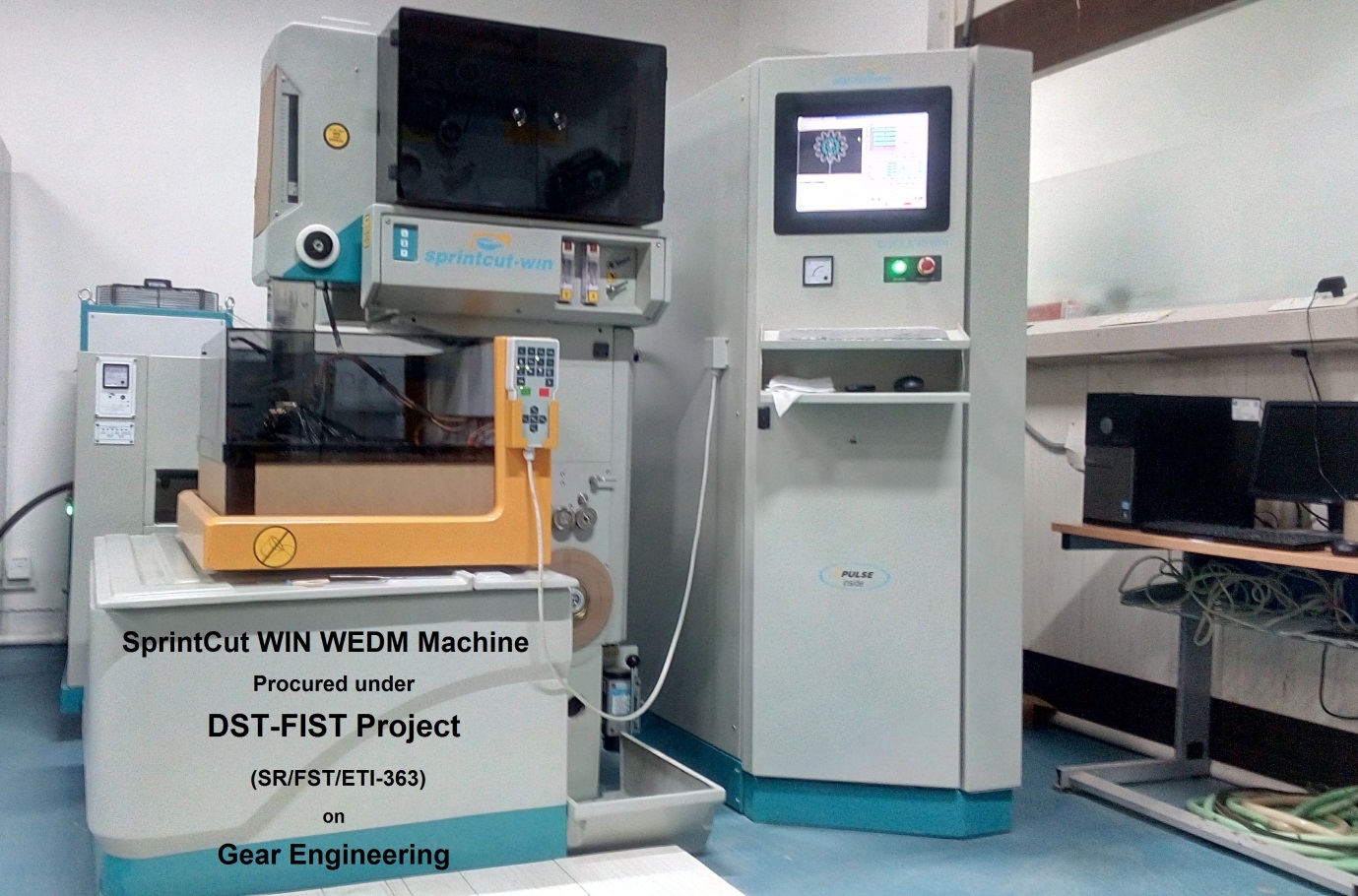

Equipment Name: CNC Wire-EDM Machine with Capability to Machine Inclined or Tapered Surfaces

Model: SprintCut WIN

Manufacturer: EMTL Sales & Service Limited

Uses: For profile cutting of inclined and tapered surfaces (i.e. manufacturing of helical, bevel, and non-circular gears) made of difficult-to-machine electrically conducting materials i.e. alloy steel, stainless steel, superalloys, Ti-alloys, etc.

|

|

Equipment Name: CNC Electro Discharge Machine

Model: Smart CNC with S 50 CNC generator

Manufacturer: ELECTRONICA MACHINE TOOLS, PUNE

Uses:

Transverse (X, Y, Z): 300, 200, 250 mm;

Maximum job weight: 300 Kg,

Maximum electrode weight: 70 Kg;

Surface Finish (Cu-St): 0.2 - 0.3 µ Ra;

Min. electrode wear (Cu-St & Gr-St) < 0.2%

Power Ratting

Motor Power: 9KV; 3 Phase; 415 Voltage

|

|

Equipment Name: CNC Milling Center

Model: EMCOMILL E 350

Manufacturer: EMCO MAIER G.M.B.H. AUSTRIA

Specifications:

Controller: Sinumerik 828D from Siemens

X-axis travel: 150 - 300 mm; Y-axis travel: 150 - 300 mm; Z-axis travel: 150 - 300 mm;

Automatic tool changer (ATC) unit with 20 tools storage capacity;

Accuracy in positioning of axes: ± 0.010 mm;

Repeatability: ±0.005 mm

Power Rating: Motor Power: 10.7 HP; 3 Phase; 440Voltage.

|

|

Equipment Name: CNC Turning Center

Model: EMCOTURN E 25

Manufacturer: EMCO MAIER G.M.B.H. AUSTRIA

Specifications:

Controller: Sinumerik 828D from Siemens

X-axis travel: 100 - 300 mm; Z-axis travel: 100 - 300 mm;

Accuracy in positioning of axes: ± 0.010 mm;

Repeatability of axes: ± 0.005 mm

No. of tooling stations: 6

Power Rating

Motor Power: 7.4 HP; 3 Phase; 440 Voltage.

|

|

Equipment Name: CNC Micro-machining Center

Model: HYPER-15

Manufacturer: SYNERGY NANO SYSTEMS, MUMBAI

Uses: Multi-Process Micro-machining Center with capability to perform micro-turning, micro-milling, Micro-EDM, Micro-ECM, and Micro-WEDM Operations

|

|

Equipment Name: 3D-Printing Machine

Model: UPRINT PLUS

Manufacturer: STRATYSYS INC. USA

Specifications:

Material: ABS

Build Size :203 x 152x 152 mm

Layer Thickness :0.254 mm

Workstation Compatibility: Windows XP/Vista/7

Wave wash support cleaning system

|

|

Equipment Name: Semi-automatic Conical Gear Cutting Machine

Model: Stanko 5A250

Manufacturer: Stanko, 180/198 Posadskogo Street, Saratov, Russia

Uses: For manufacturing bevel gears.

|

|

Equipment Name: Gear Hobbing Machine

Model:

Manufacturer: D.G. Panchal, Ahmedabad

Specifications: Maximum module 6 mm; Gear diameter range: 75-250 mm; Range of face width 150-300 mm; No. teeth cut: 4-400; RPM of hob spindle: 20-130; No. of speeds of hob spindle 6; Cutter helix angle: 0-45 degrees for both right-hand helix and left-hand helix.

Uses: For manufacturing spur and helical gears

|

|

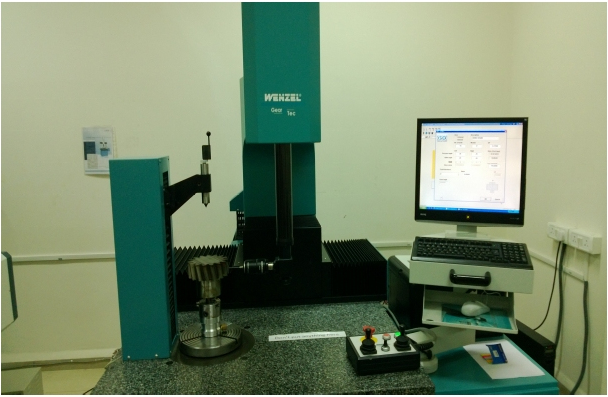

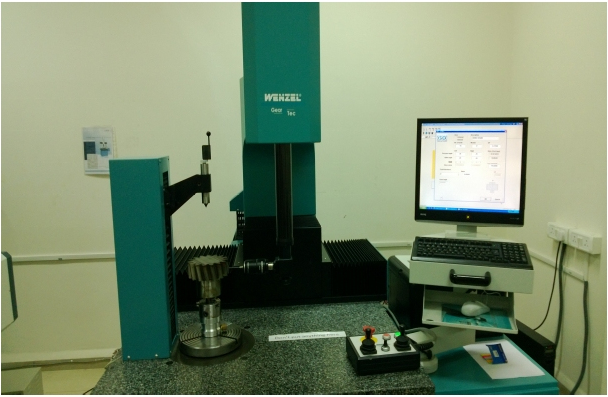

Equipment Name: CNC gear metrology machine

Model: SmartGear 500 with Reninshaw scanning probe system SP600; Rotary table L250 RT IN along with the required supporting software TGear, TMain, TStylus, TCali, TAmo,

Manufacturer: Wenzel GearTec, Germany

Specifications: Max. gear diameter 270 mm; minimum internal gear diameter: 12 mm; maximum measurable face width: 300 mm; maximum helix angle 900 ; Control: 4-axis power PC controller; Accuracy: Gear measuring machine for gear measurements in accordance with VDI/VDE 2612/2613 Group 2. Travel range: X axis: 500 mm; Y axis: 450 mm; Z axis: 400 mm.

Uses: For fully automatic, fast, and precise measurement and analysis of gears of following type: Straight and helical cylindrical gears, Spiral & hypoid bevel gears, Crown gears, Conical cylindrical gears, Segment gears, Beveloid gears, Synchronous gears, Hobs, Cylindrical worm shafts, Shaving cutters, Shaper Cutters, Pinion-shaped cutters with capability for the automatic measurement and analysis of 3D-geometry, form and position, diameters and distances.

|

|

Equipment Name: Manual Gear Metrology Machine

Model: MAAG PH 25

Manufacturer: Prime Technologies, Mumbai

Specifications: Computerized measurement of gear lead, profile, pitch, and runout of spur and helical gears along with the supporting software GEARMAS I and GEARMAS II.

(Procured from CSIR Project No 22(0468)/09/EMR-II of Prof. Neelesh Kumar Jain)

|

|

Equipment Name: Abrasive Jet Machining (AJM) apparatus (Developed in-house)

Model:

Developed by: Prasad Kulkarni, Pratik Bagal and Devkant Singh (2011 batch BTech students of Mechanical Engineering)

Uses: For drilling holes and cutting profiles in thin ceramics.

|

|

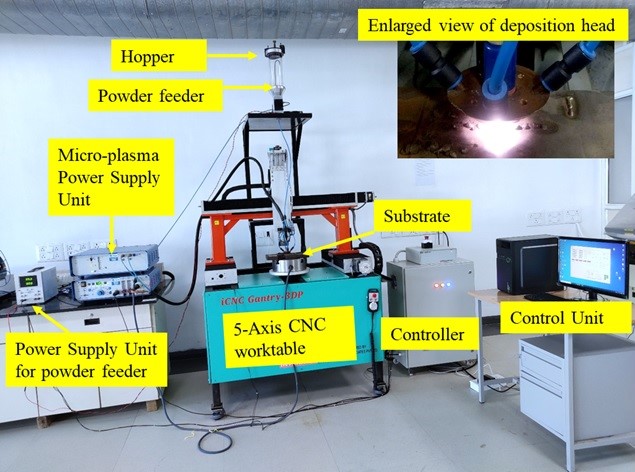

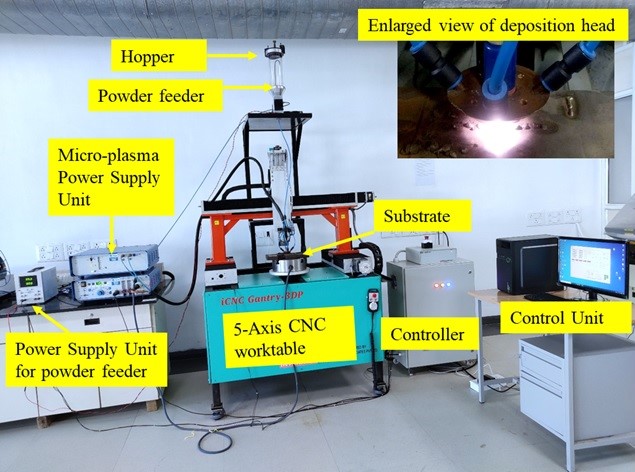

Apparatus Name: Micro-Plasma Transferred Arc based Metal Additive Manufacturing (Developed in-house)

Developed by: Suyog Jhavar, Mayur S Sawant (PhD student of Mechanical Engineering completed PhD in 2014 and 2018 respectively)

Use: For meso-scale additive manufacturing of different metallic and biocompatible materials using in wire, powder, both wire and powder, and particulate form using maximum power of 440 Watts.

Innovation: 3D-printing or additive manufacturing machine for high point metallic materials using micro-plasma transferred arc. It uses maximum current of 20 A and maximum power of 440 Watts only. It has computer numerical control on 4 axes. It has provisions to supply deposition material in powder form, wire form, or both combined. It has been used 3D printing of the following materials:

Titanium alloy: Ti-6Al-4V (powder and wire form)

Superalloy: Inconel 625 (wire)

Tool materials: Stellite, P25, HD12 (powder and wire form)

It has been used for micro-joining of thin sheets (< 3 mm thickness) of stainless steel, mild steel. It is also being used to develop high and medium entropy alloys, shape memory materials, functionally graded materials.

4 PhD and 4 MTech theses completed and more than 25 journal publications using this machine. One patent has been filed.

TRL: 4-5

|

|

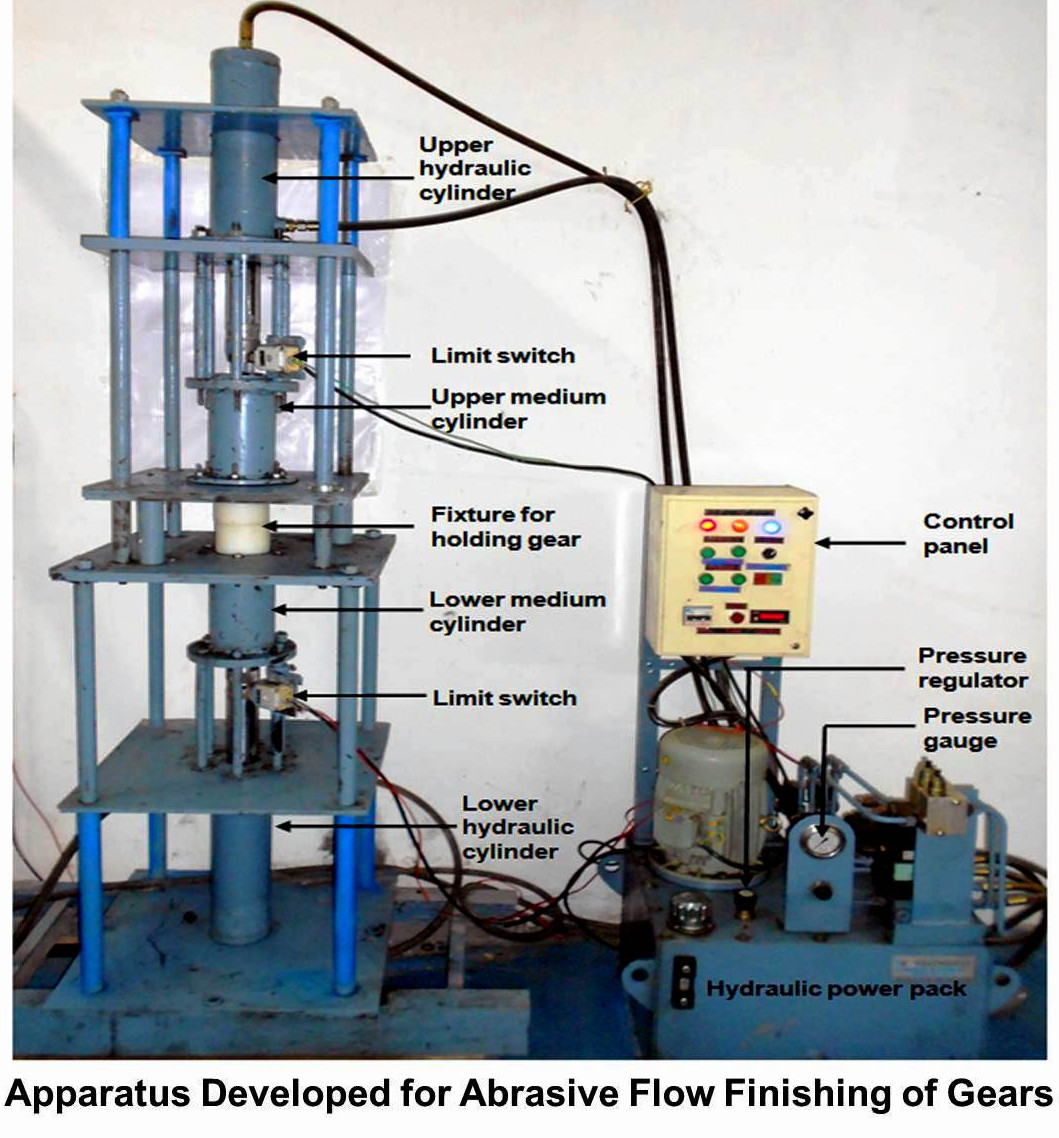

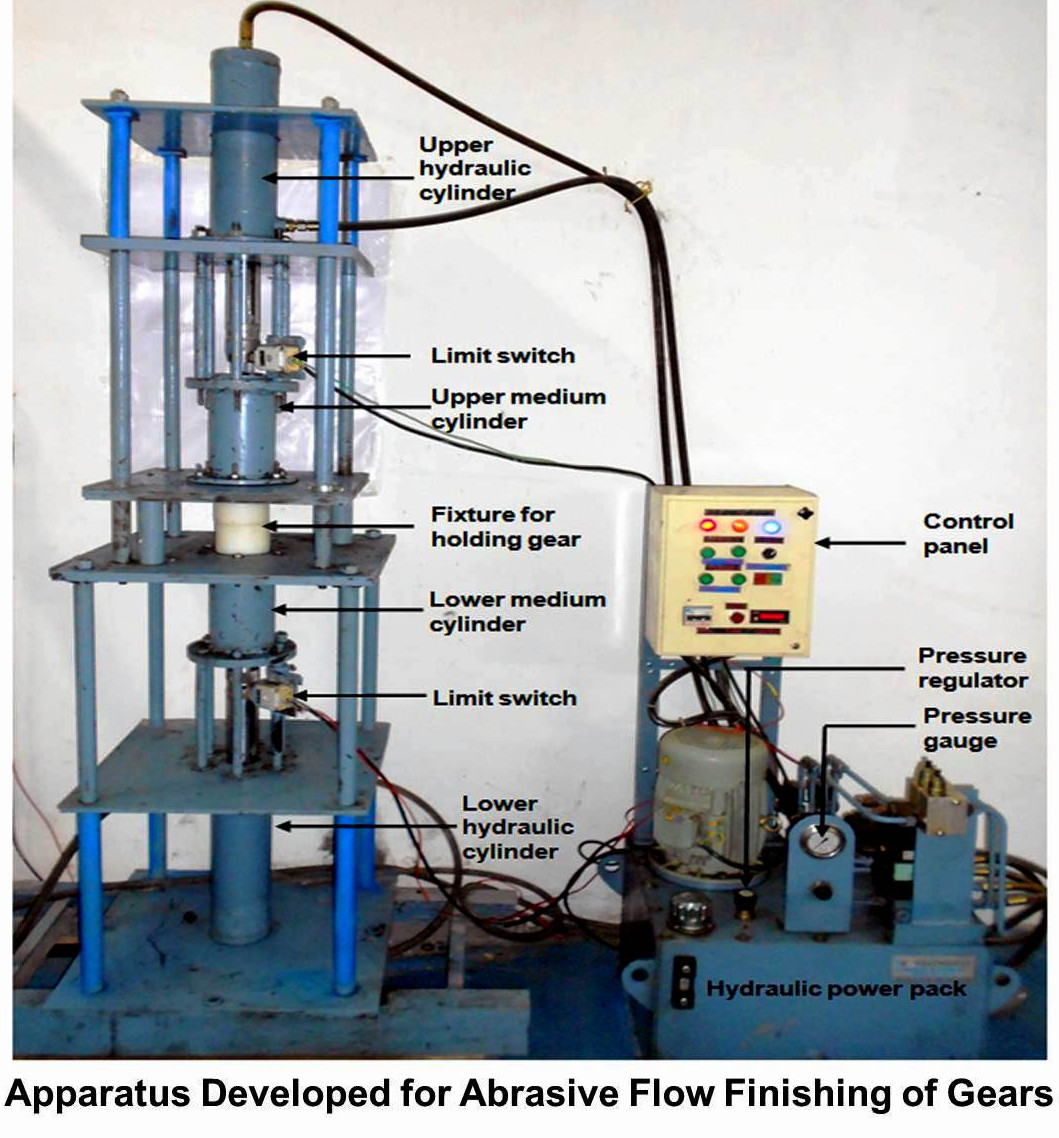

Equipment Name: Abrasive flow finishing (AFF) apparatus (Developed in-house)

Model:

Developed by: Anand C. Petare (Part-time PhD student of Mechanical Engineering, completed PhD in 2020)

Uses: For fine finishing different types of gears and other workpieces

Innovation: Abrasive flow finishing (AFF) machine along with fixtures has been developed to impart high quality finishing to spur, helical and bevel gears. Mixture of molding clay, silicon carbide abrasives, and silicone oil has been as putty for finishing different types of gears. It has improved the gear quality up to 7 DIN standard. The machine is very robust. It can finish multiple gears simultaneously. It is being explore to improve surface finish of additively manufactured parts.

|

|

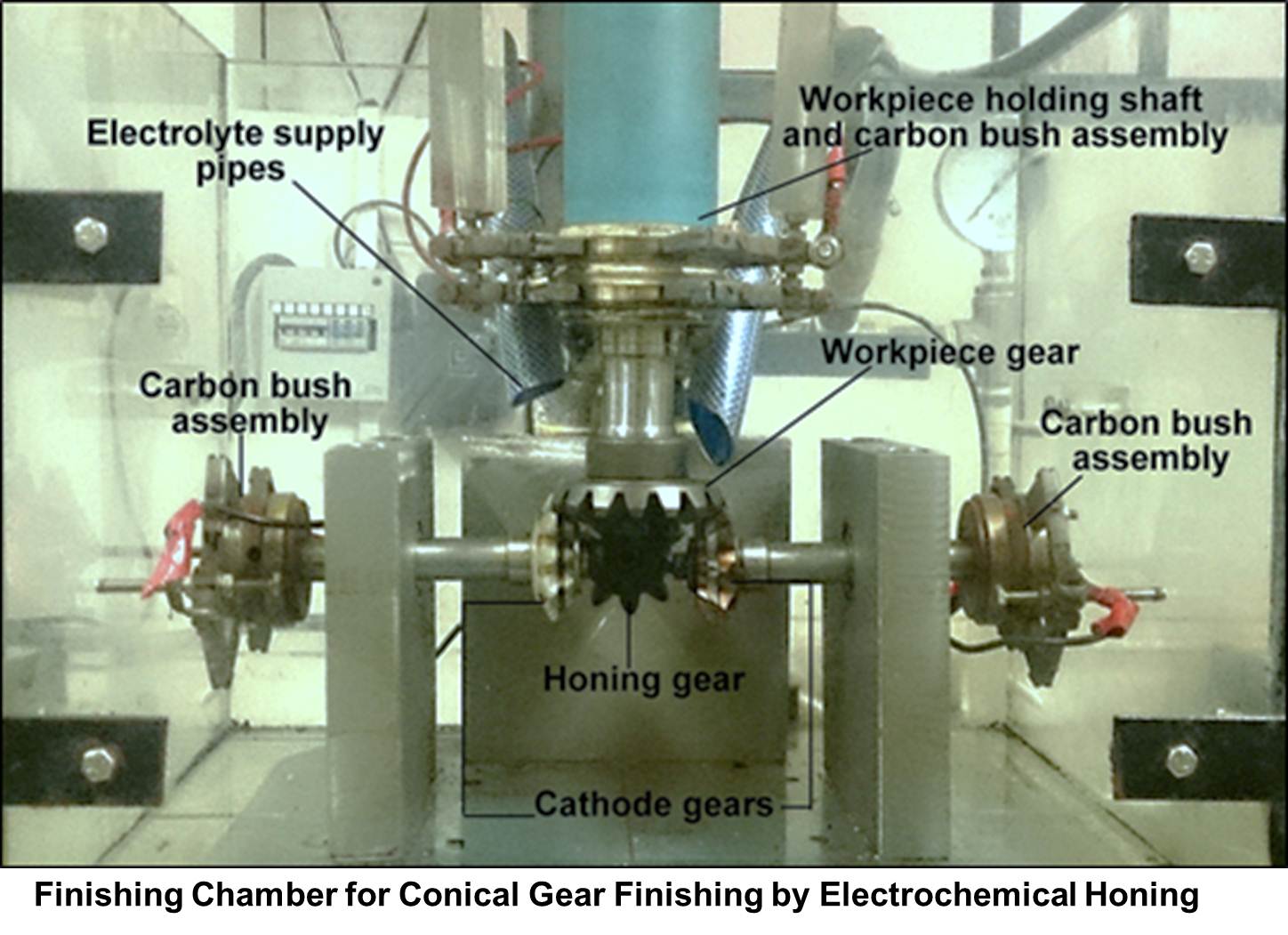

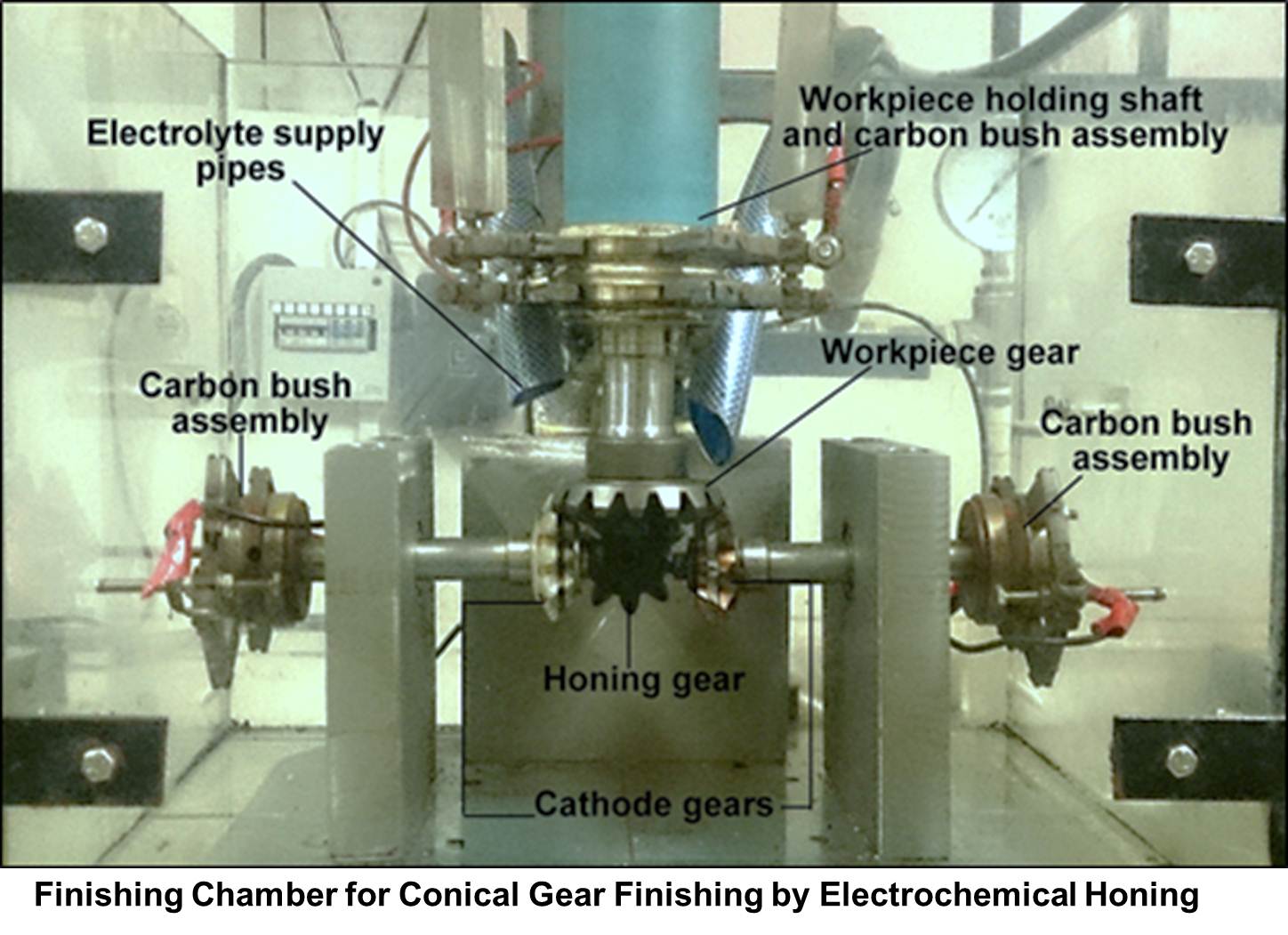

Equipment Name: Electrochemical Honing (ECH) apparatus (Developed in-house)

Model:

Developed by: Javed Habib Shaikh and Sunil Pathak (PhD students of Mechanical Engineering completed PhD program in 2014 and 2016 respectively)

Uses: For high quality finishing of conical and cylindrical gears.

Innovation: Novel concept of twin complementary cathode gears has been envisaged to develop electrochemical honing (ECH) machine for imparting high quality finishing to bevel gears. Commercially used alloy in automotive applications 20MnCr5 was used as the bevel gear material. It has provision to supply either continuous or pulsed DC power supply leading to pulse-ECH (PECH). PECH has given better performance than ECH. It improved the bevel gear quality up to 6 DIN standard. Plasma nitriding has also been used to enhance performance of PECH.

|

|

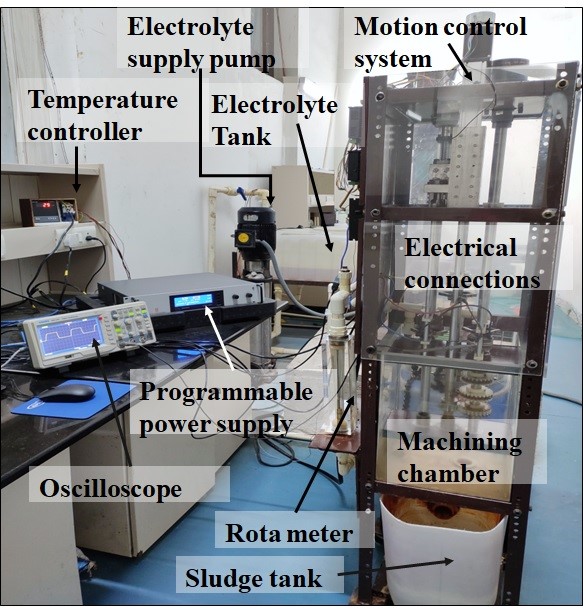

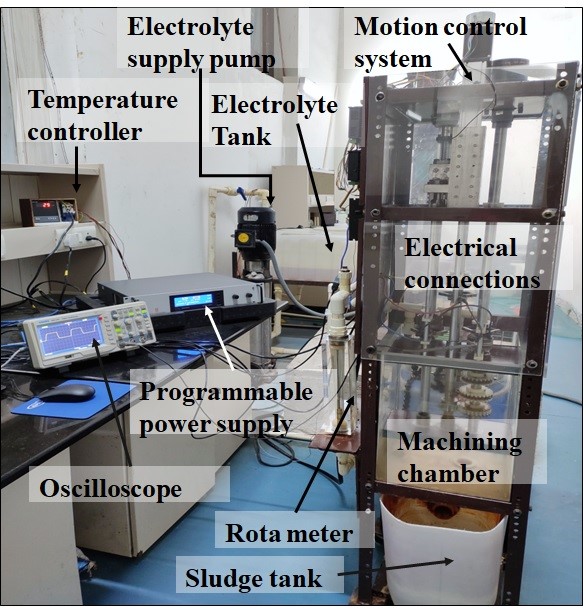

Apparatus Name: Non-Contact Flank Modification Machine for Gears by Pulsed Electrochemical Process (Developed in-house)

Developed by: Vivek Rana (DST-INSPIRE Fellow and student of MTech and PhD dual degree Program, completed PhD in Sep 2023)

Use: Pulsed electrolytic dissolution (PED) based machine to impart five types of flank modifications namely tip relief, root relief, end relief, flank crowning, and profile crowning to spur gears.

Innovation: Design of five cathode gears for imparting these flank modifications. The machine has provisions to impart either of any five flank modifications, their combination or all five flank modifications simultaneously. Modified gears have much better functional performance and demonstrated better noise and vibration characteristics than the unmodified gears. Five theoretical models have also been developed to predict each type of modification.

|

|

Equipment Name: Computerized Dual Flank Roll Tester for Conical Gears

Model: DO 125 K PC

Manufacturer: M/S Gearspect India Pvt. Ltd., Pune

Uses:

- To mount the pair on the specified center distance within accuracy of 0.05 mm and mesh with each other for dual flank roll testing of conical gears

- By meshing the gears with zero back lash, to check the tooth-to-tooth composite error and total composite error of the pair.

- To check and ensure backlash in the pair.

- To check the transfer of blue from pinion to gear to assess the proper meshing of the gears.

- Rolling of gear with a master pinion and vice versa.

- Decide action for correction of both or any one of the gear to achieve the desired meshing.

|

|

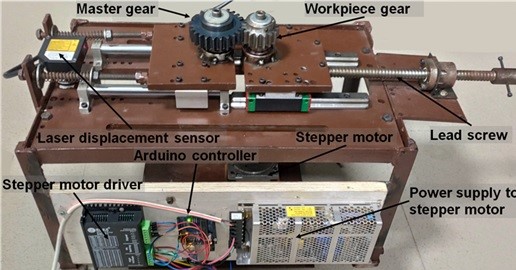

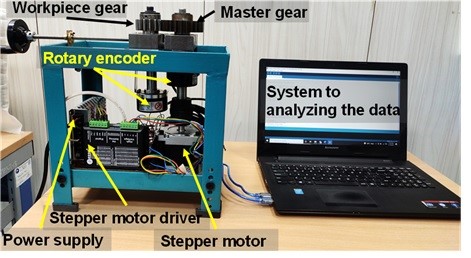

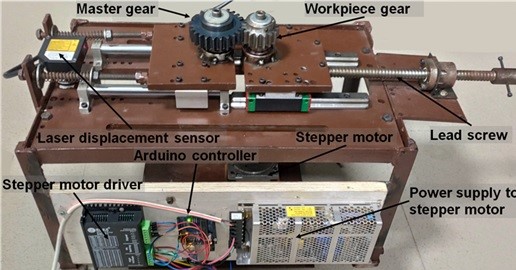

Equipment Name: Dual Flank Roll Tester for Cylindrical Gears (Developed in-house)

Developed by: Rajat Kasliwal (MTech student, completed MTech in July 2017)

Use: To measure tooth-to-tooth composite error, total composite error, and radial runout of a test gear by allowing both flank surfaces of its tooth to contact with flank surfaces of master gear tooth during their rolling action.

|

|

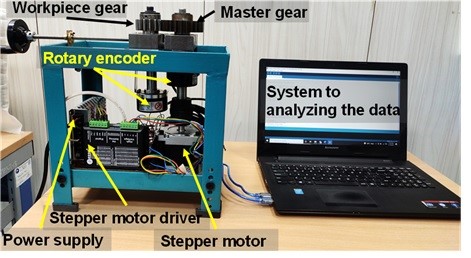

Equipment Name: Single Flank Roll Tester for Cylindrical Gears (Developed in-house)

Developed by: Vivek Rana (DST-INSPIRE Fellow and student of MTech and PhD dual degree Program, completed PhD in Sep 2023)

Use: To measure total transmission error (also known as total tangential composite error), tooth-to-tooth transmission error (also referred to as tooth-to-tooth tangential composite error), longwave transmission error (also called as longwave tangential composite error), total pitch error of a test gear by allowing only its one flank surface to contact with a flank surface of master gear at any point of time during their rolling action

|

|

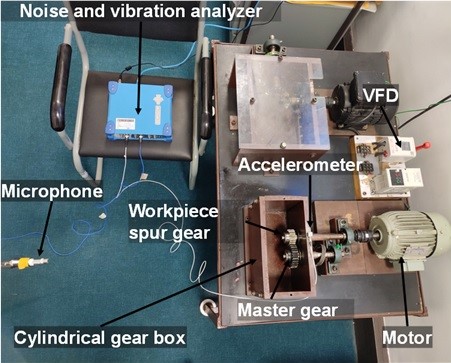

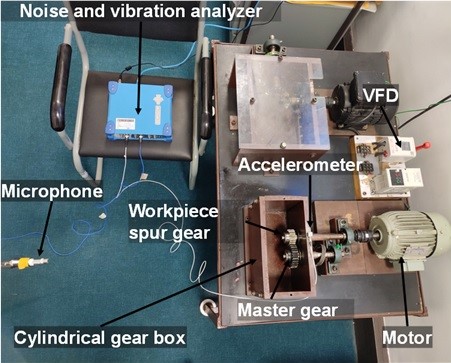

Equipment Name: Test Rig for Measuring Noise and Vibrations of Gears (Developed in-house)

Developed by: Gaurav Kumar and Rahul Kashyap (MTech students completed MTech in Julu 2017)

Use: To measure noise and vibrations of cylindrical and conical gears using Noise and Vibration Analyzer and Sound Intensity Probe

|

|

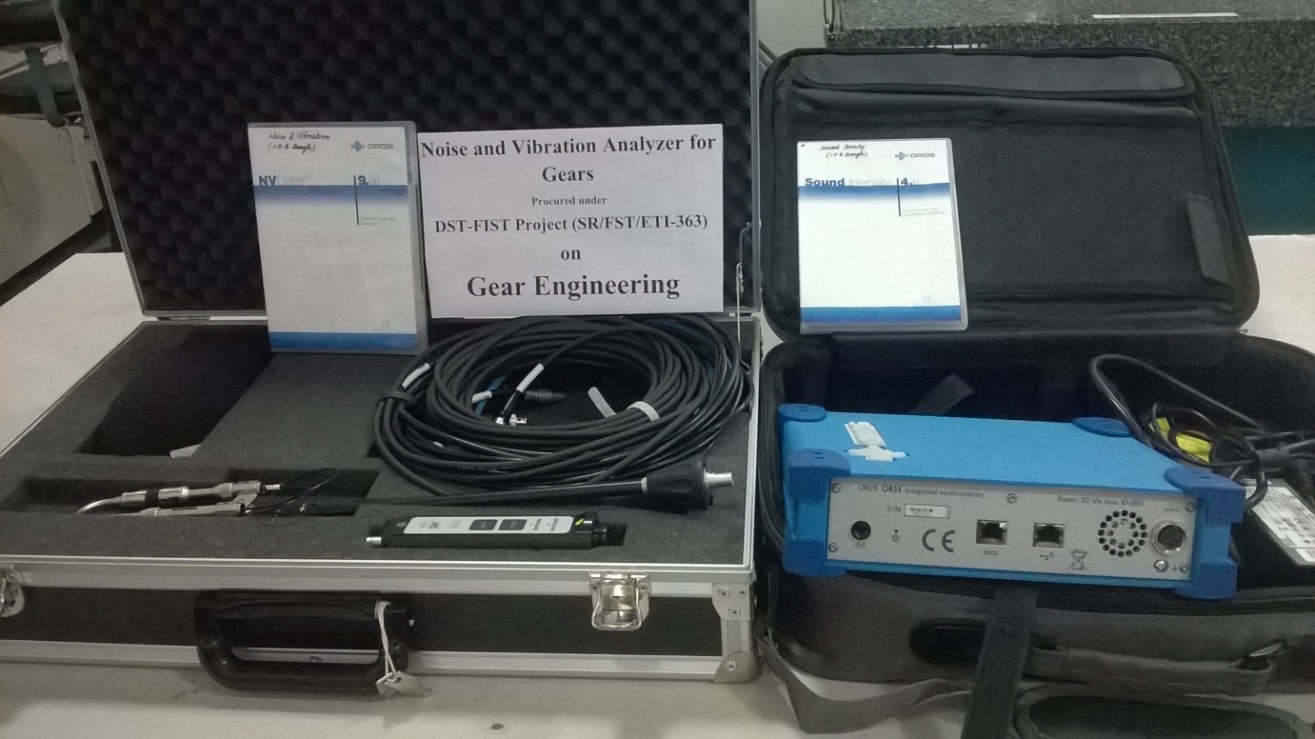

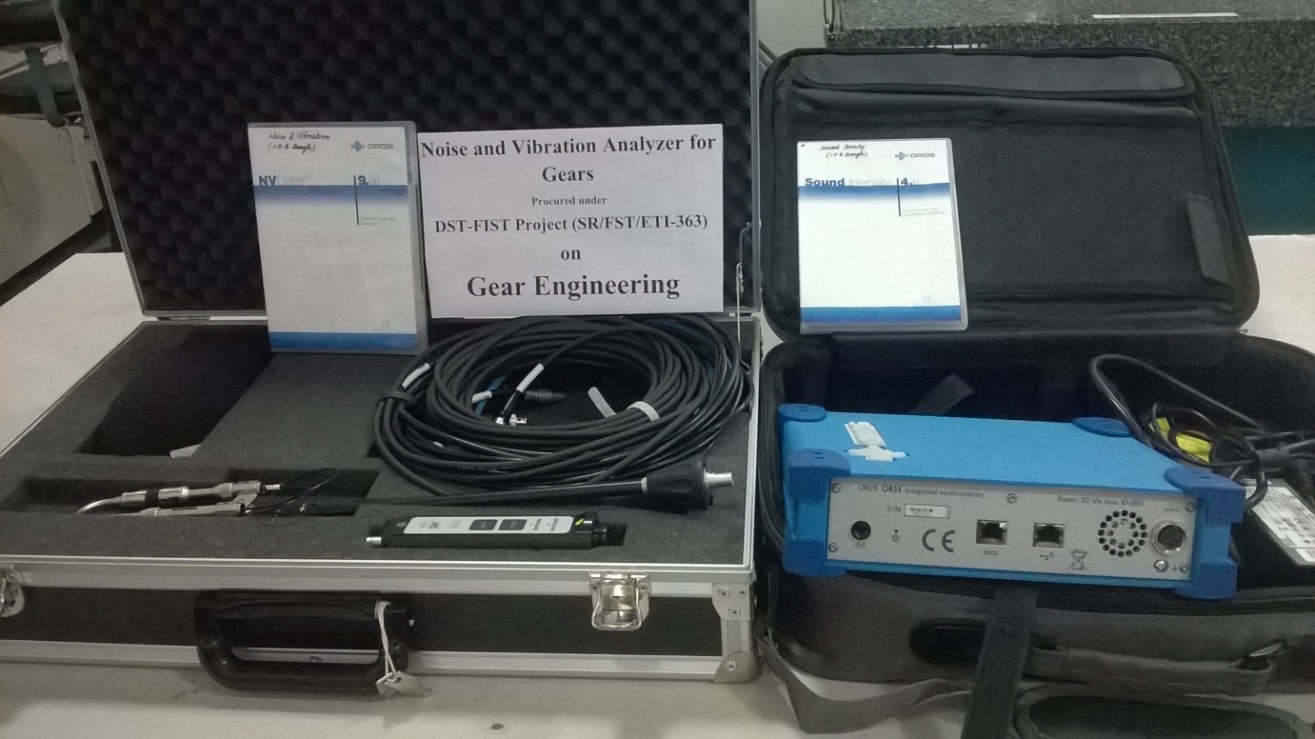

Equipment Name: Noise and Vibration Analyzer for Gears with Sound Intensity Probe

Model: OR35-FREQ-4

Manufacturer: M/s. OROS France

Uses: For analyzing vibration and noise between two meshing gears and to know location of source of noise

|

|

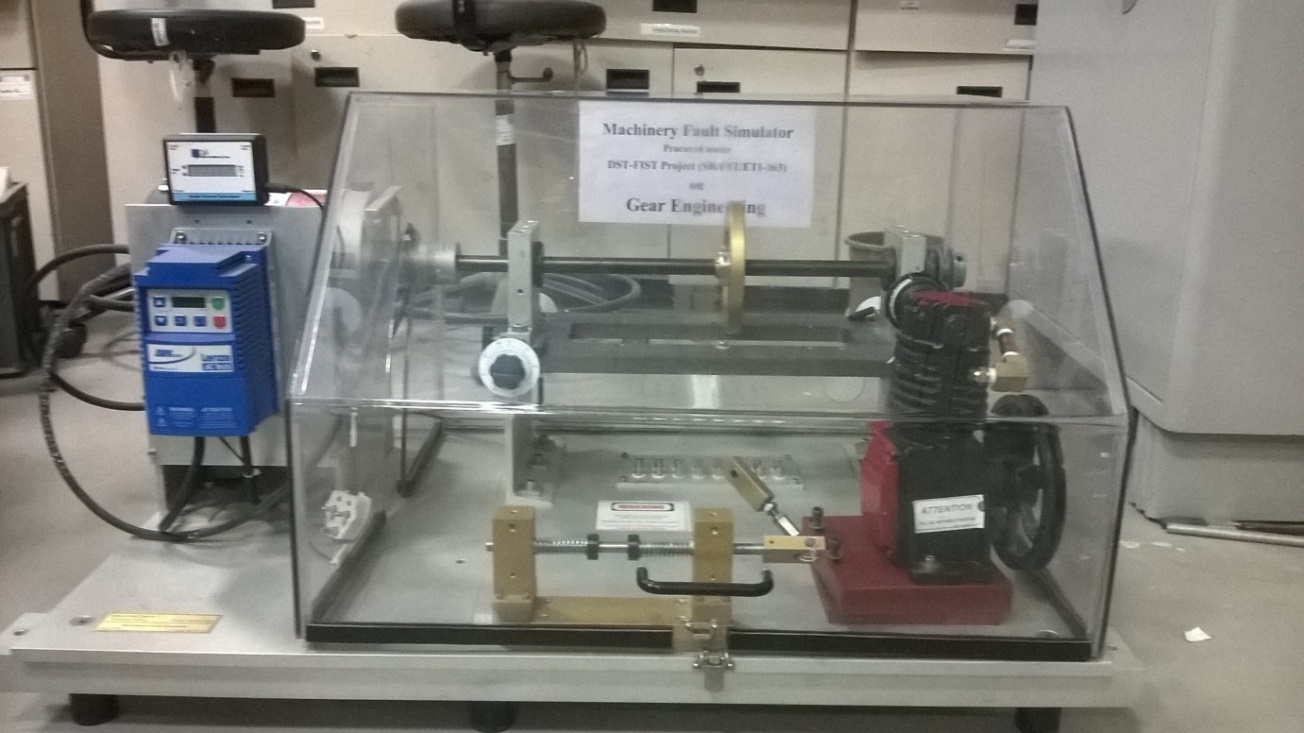

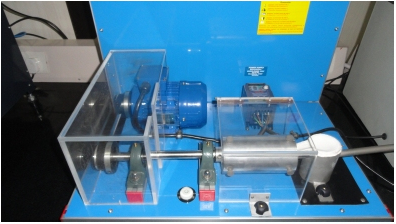

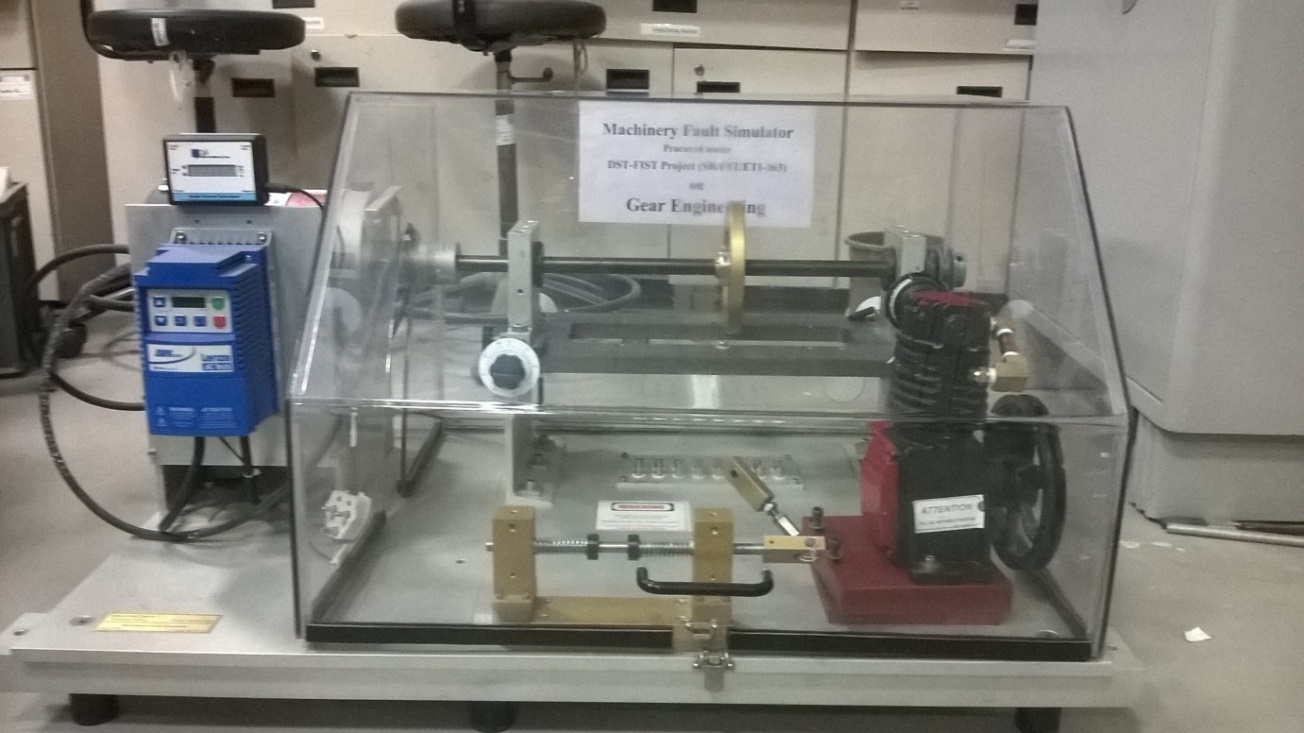

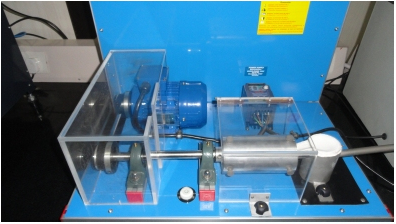

Equipment Name: Machinery Fault Simulator

Models: MFS 2010 PK-7

Manufacturer: Spectraquest Inc. USA

Uses"

- For introducing controlled and calibrated faults.

- To study the vibration spectra of common faults, learn fault signatures and validate rules provided in training courses.

- Bench top machine for hands-on training and skill sharpening.

- Learn machine condition monitoring and predictive maintenance.

- Manual with exercises for individually paced study.

- To learn resonance, variable speed, gearbox, and belt drive diagnostics.

- To learn to determine vibration transmission path and perform root cause analysis.

- To study correlation among vibration, motor current, and noise spectra.

- To model rotor dynamics and its effects on fault signatures.

- To validate balancing procedures above and below the first critical resonance.

- To study reciprocating mechanisms

- For foundation studies

- For signal processing techniques

- Variable speed/load effects

- For motor current analysis

- To study rotor dynamics

- For operating deflection shape and modal analysis

- To optimize sensor mounting

- For vibration training

- For analyst certification

|

|

Equipment Name: Foundry engineering equipment

Models: VWT Wet Tensile Tester Suitable for Wet Tensile Strength of green sand. Capacity 60 gm/Cm 2 Motorized Loading unloading Mechanism, Load Cell, pneumatic cylinder hot plate for heat the specimen up to 300 o C Digital Strength Indicator. Timer, Should Work on 230 volt, 50 cycles, 750 watts Power Supply

MOULD STRENGTH TESTER: With Dial Indicator with Special Tip to Measure Compression Strength on direct Mould. Capacity 2 Kg/cm2

MOULD HARDNESS TESTER (DIGITAL) ('B' SCALE): With Digital Dial Indicator To Measure Hardness of Mould 0 - 100 No.

Manufacturer: VERSATILE EQUIPMENTS PVT. LTD, KOLHAPUR

|

|

Equipment Name: Foundry Instruction Set

Model: MCEN Centrifugal Casting Demonstration Unit

MCAM Bell casting Demonstration Unit

MCLA Sand Casting Demonstration Unit

Manufacturer: EDIBON Inc. SPAIN

Uses:

For the demonstration of

(i) Sand casting experiments with three different patterns such as bell, anvil and anchor, etc.

(ii) Making up a casting with cavity (pipe reduction)

(iii) Centrifugal casting by producing a metal body in a rotating die

|